I had been vacillating on the Trixie build; I knew that I needed to complete the focuser board in order to really move forward, and I also knew that I could finish a board in about 20 minutes with the drill press, but that the time spent building the piece in CAD would come in handy if anything went wrong. I finally bit the bullet and built the thing in LibreCAD, and I was certainly glad that I did — the first cut came out just right, except that the focuser was mounted 90º rotated in the wrong direction (eye roll). 5 minutes of tweaking in CamBam, and I was ready to re-cut. Second time it came out just right.

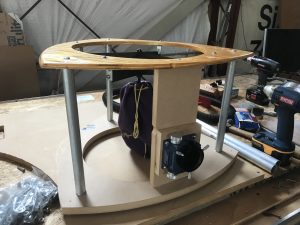

I had sort of eyeballed everything, and it was nice to see that it came right together without any tweaking.

With the focuser installed, I’m ready to measure the focal length, so of course today was the first day of rain in the past 2 months…

Once the focal length is determined, I’ll need to build 6 new pole seats. The truss poles have a compound angle; the “spread” angle is determined by the focal length, but the “rake” angle is always 30º, because equilateral triangles. One way or the other, I needed to build a jig for the drill press, and again I turned to the CNC machine, to make life easier as I need to tweak things.

Here’s the jig, all ready to go.

I made a rough guess of 22º for the spread angle, but I think that there is some kind of complementary angle thing happening, because obviously, this is not quite right.

Because this is CAD, I can rebuild the angled beds pretty easily. At this point, I just need the real angles, and I can tweak it until it works.

With pole seats and the focuser, I am really, really close to having Trixie up and running again.

MOST COMMENTED

Observatory

Observatory 2.0 – Time has come today!

General / Maintenance

First Light, a deeper look

Mount / Observatory / Telescope

Observatory 2.0 – Result!

Observatory

Observatory 2.0 – The Pier goes in

Gear / General / Maintenance

Martin Farmer Wormblock installation notes

Deep Sky / Long Exposure Photography

NGC2244, The Rosette Nebula

Deep Sky / Long Exposure Photography

Another beautiful night.